Case study 1

The Challenge

A food company’s Rotary Mill displayed the following problems:

- Drive End Bearing was Very Noisy

- Under performing

- Loss of production

- Increased safety risks

The Methodology

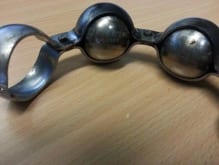

Vibration tests and later bearing failure analysis were carried out to identify:

- Source of the noise

- The severity of the damage

- The root cause of the failure

The Outcome

After implementing all the corrective actions recommended, there was the following outcomes:

- Increased Mill performance to optimum level

- Increased revenue by 18%

- Decreased safety risks

- Increased reliability of asset from 80% to 98%

- Increased revenue by 18% 18%

- Increased reliability of asset to 98% 98%